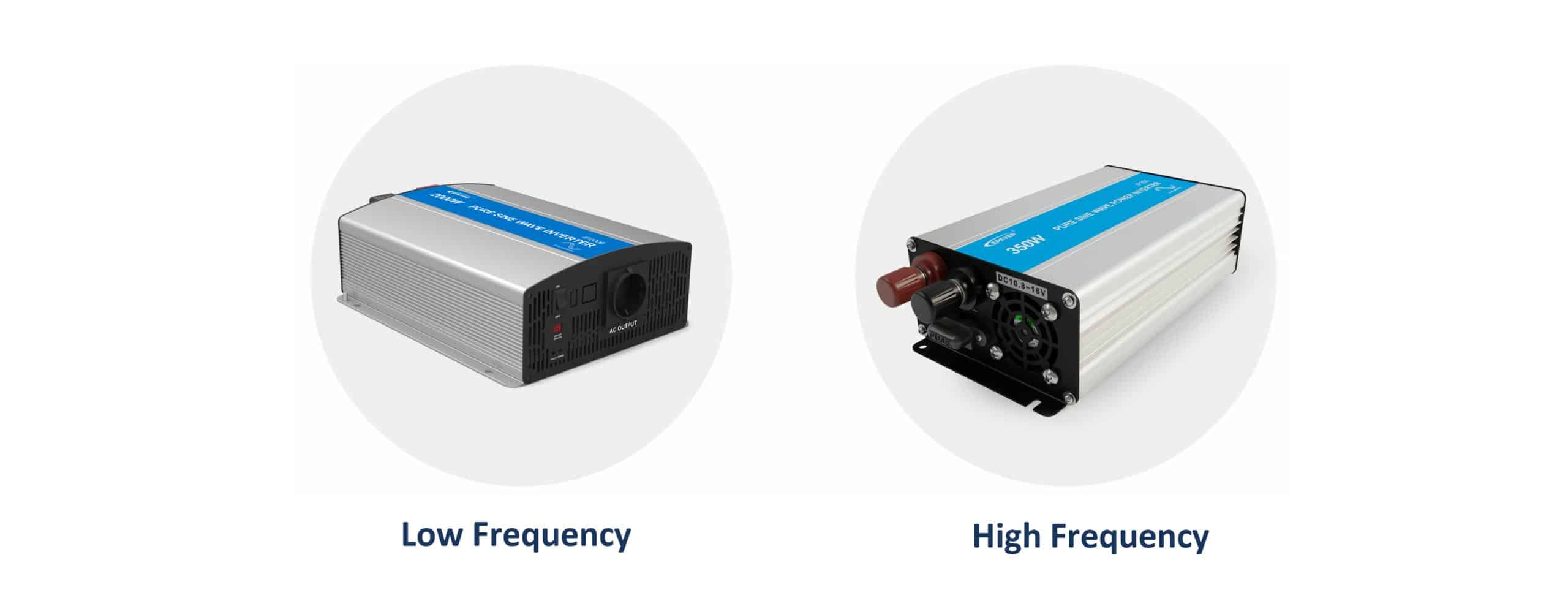

High-Frequency vs. Low-Frequency Inverters

Inverters are crucial components in solar power systems, uninterruptible power supplies (UPS), and other electrical systems. Their job is to convert DC (direct current) power into AC (alternating current) power, making it usable for household appliances, industrial equipment, and electronic devices. Two main types of inverters are high-frequency and low-frequency inverters. Each type has its advantages and disadvantages, making them more suitable for specific applications. Let’s explore the key differences between them.

1. Technology and Design

High-Frequency Inverters: High-frequency inverters use high-speed switching transistors like MOSFETs (metal-oxide-semiconductor field-effect transistors) to convert DC to AC. These transistors operate at high frequencies (often tens of kilohertz to hundreds of kilohertz). The inverter steps up the voltage using lightweight transformers or inductors, followed by the conversion to AC.

Low-Frequency Inverters: Low-frequency inverters use heavy, iron-core transformers to step up the voltage from DC to AC. These transformers operate at the utility grid frequency of 50 Hz or 60 Hz, depending on the region. Due to the lower operating frequency, these inverters tend to be bulkier and heavier.

2. Size and Weight

High-Frequency Inverters: One of the biggest advantages of high-frequency inverters is their compact size and lightweight design. Since they use smaller, lighter transformers and components, they are ideal for portable applications and installations where space is limited, such as in RVs, boats, or small solar setups.

Low-Frequency Inverters: Low-frequency inverters are larger and heavier due to the use of iron-core transformers. These inverters can weigh significantly more than high-frequency models with the same power rating, making them less suitable for mobile or space-constrained installations.

3. Efficiency

High-Frequency Inverters: High-frequency inverters are generally more efficient in terms of energy conversion, with efficiencies ranging from 90% to 96%. They can operate with less power loss during the DC-to-AC conversion process, making them ideal for applications where energy efficiency is critical.

Low-Frequency Inverters: Low-frequency inverters are slightly less efficient, with efficiency ratings between 85% and 90%. This is because the larger transformers generate more heat and energy loss. However, they offer better efficiency when running inductive loads like motors and compressors, making them suitable for industrial or heavy-duty applications.

4. Power Handling and Surge Capacity

High-Frequency Inverters: High-frequency inverters can handle moderate surges, but their surge capacity is generally lower than low-frequency inverters. They may struggle to run devices with high startup surges, such as refrigerators, air conditioners, or pumps, without overloading.

Low-Frequency Inverters: Low-frequency inverters are known for their excellent surge capacity, often handling 2 to 3 times their rated power for short periods. This makes them ideal for running inductive loads or equipment that require high surge currents at startup, such as industrial machinery or large appliances.

5. Durability and Reliability

High-Frequency Inverters: While high-frequency inverters are more efficient and compact, they may not be as durable in harsh environments. Due to the use of smaller components and high-speed switching, they are more susceptible to heat and electromagnetic interference (EMI), which can lead to shorter lifespans if not properly ventilated or protected.

Low-Frequency Inverters: Low-frequency inverters are generally considered more robust and reliable. Their larger, simpler transformers are less affected by temperature fluctuations and EMI, making them ideal for use in industrial settings or off-grid systems where durability is essential. They also tend to have longer lifespans compared to high-frequency inverters.

6. Cost

High-Frequency Inverters: Due to their compact size and fewer materials, high-frequency inverters are generally more cost-effective upfront. They are less expensive to manufacture and are widely used in small to medium-sized solar installations, mobile applications, and backup power systems.

Low-Frequency Inverters: Low-frequency inverters tend to be more expensive due to the use of heavy, iron-core transformers. However, they are more economical in the long run for high-power, heavy-duty applications, where their surge capacity, durability, and long lifespan outweigh the initial cost.

7. Applications

High-Frequency Inverters:

- Solar power systems (especially small to medium-sized setups)

- Portable power solutions (e.g., RVs, boats, and mobile homes)

- Backup power for homes and small businesses

- Low to medium power appliances and electronics

Low-Frequency Inverters:

- Industrial applications (e.g., machinery, compressors, and motors)

- Off-grid solar power systems

- Heavy-duty power tools and equipment

- Large home appliances (e.g., refrigerators, air conditioners)

- Backup power for commercial facilities and industrial sites

Conclusion: Which Inverter Should You Choose?

The decision between a high-frequency and low-frequency inverter depends largely on your specific needs:

High-frequency inverters are ideal for applications that require compactness, energy efficiency, and low cost. They are well-suited for portable applications, smaller solar setups, and systems where weight and size are critical.

Low-frequency inverters are better suited for heavy-duty, industrial applications that require high surge capacities, durability, and long-term reliability. They are ideal for running inductive loads, off-grid power systems, and equipment that demands significant power at startup.

In summary, if you need a lightweight, efficient, and budget-friendly solution, a high-frequency inverter is your best option. However, if your priority is durability and handling high surge loads, especially in demanding environments, a low-frequency inverter is the better choice.