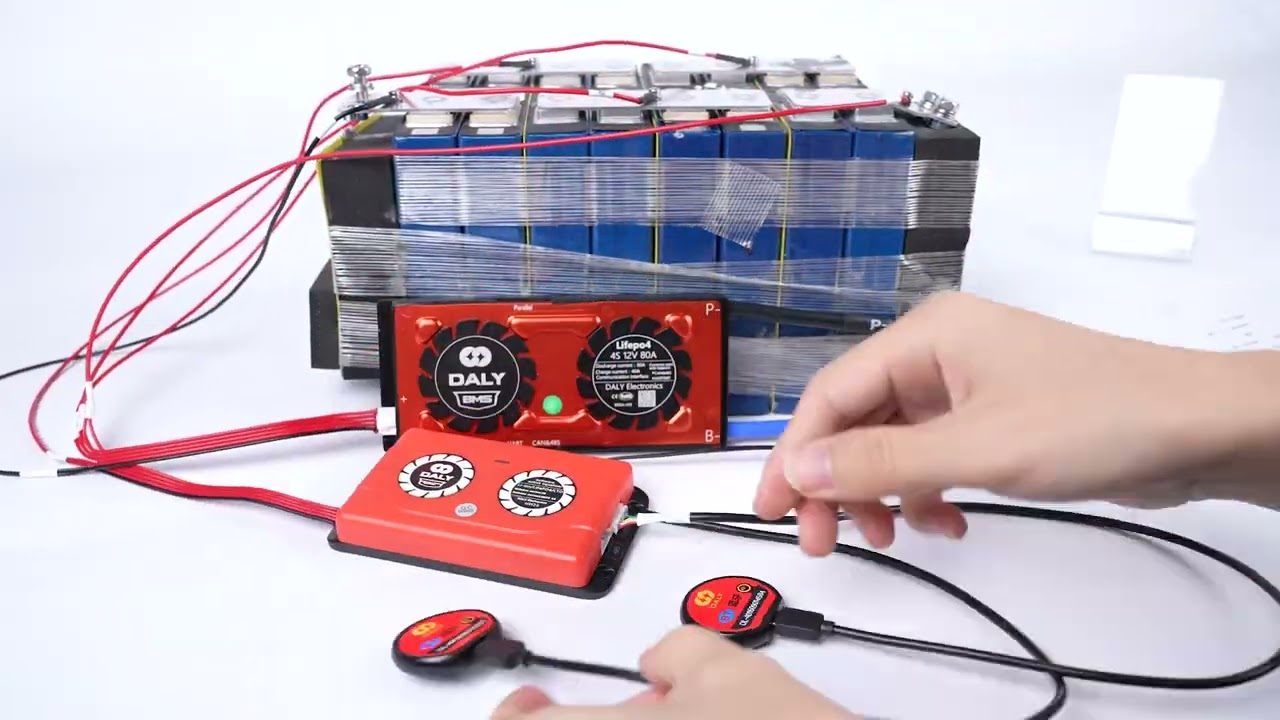

Prismatic vs Cylindrical LiFePO4 Battery

When comparing prismatic versus cylindrical LiFePO₄ (lithium iron phosphate) batteries, each has its own advantages depending on the application. Here’s a breakdown of both types to help determine which is better for your needs:

1. Prismatic LiFePO₄ Batteries

Advantages:

- Higher Energy Density per Cell: Prismatic cells typically have a larger capacity per cell, meaning fewer cells are needed to reach the desired energy storage, reducing the complexity of wiring and management.

- Compact and Lightweight: Prismatic cells are often flatter and more rectangular, making them easier to stack and fit into tight spaces. They’re ideal for applications where space and weight are crucial, like electric vehicles (EVs) and stationary energy storage.

- Better for Large Capacity Applications: Prismatic cells are generally favored in higher capacity applications (e.g., 100Ah or more), making them ideal for solar storage systems, electric cars, and backup power.

- Less Complex Assembly: Fewer cells are required for a high-capacity battery pack, simplifying the battery management system (BMS) and reducing potential points of failure.

Disadvantages:

- Lower Heat Dissipation: Prismatic cells tend to have lower heat dissipation compared to cylindrical cells, which can affect performance in high-current applications.

- Durability: They are less tolerant to mechanical stress and vibration, making them less suitable for environments where ruggedness is required.

2. Cylindrical LiFePO₄ Batteries

Advantages:

- Higher Mechanical Durability: Cylindrical cells are more robust and can handle physical stress, such as vibrations and impacts, better than prismatic cells. This makes them suitable for applications in rough environments.

- Better Heat Dissipation: Due to their shape, cylindrical cells tend to dissipate heat more effectively, which is an advantage in high-power applications where heat management is critical.

- Standardized Sizes: Cylindrical cells, like 18650 or 21700, are standardized, making them more easily replaceable and allowing for consistent production quality.

- Lower Cost (in Mass Production): Cylindrical cells are mass-produced, which can make them cheaper on a per-cell basis compared to prismatic cells.

Disadvantages:

- More Complex Assembly: Since cylindrical cells typically have lower capacity per cell, more cells are needed to achieve the desired energy storage, leading to more complex wiring and a larger battery management system (BMS).

- Bulkier in Packs: Cylindrical cells, when assembled into battery packs, can create more space inefficiencies compared to prismatic cells due to their rounded shape.

Key Considerations:

Application:

- Prismatic batteries are better suited for high-capacity applications (e.g., solar storage, EVs, home energy systems) where space is a premium, and the overall energy density is critical.

- Cylindrical batteries are favored for smaller, more modular applications (e.g., power tools, e-bikes, portable electronics) where heat management, durability, and cost-effectiveness are important.

Durability:

- For rugged or mobile environments (e.g., electric bikes or industrial tools), cylindrical cells are generally more durable due to their ability to withstand physical shocks and better heat dissipation.

- For stationary applications like home energy storage, prismatic cells are often preferred because they offer more compact, high-energy solutions.

Cost:

- Cylindrical cells may be more cost-effective in mass production due to standardization.

- Prismatic cells, while more expensive in certain cases, offer fewer cells per battery pack, potentially simplifying system design.

Conclusion:

- Prismatic LiFePO₄ Batteries are better for applications requiring high energy density, space efficiency, and less complex assembly, such as electric vehicles, solar storage systems, and backup power applications.

- Cylindrical LiFePO₄ Batteries are better for applications requiring mechanical durability, better heat dissipation, and high-power performance, such as power tools, rugged environments, and devices where modularity and scalability are essential.

The choice depends on your specific application needs: for high capacity and compact designs, prismatic may be better; for durability and heat management, cylindrical is often the choice.